Asian lacquer

by Kenta Takeshige

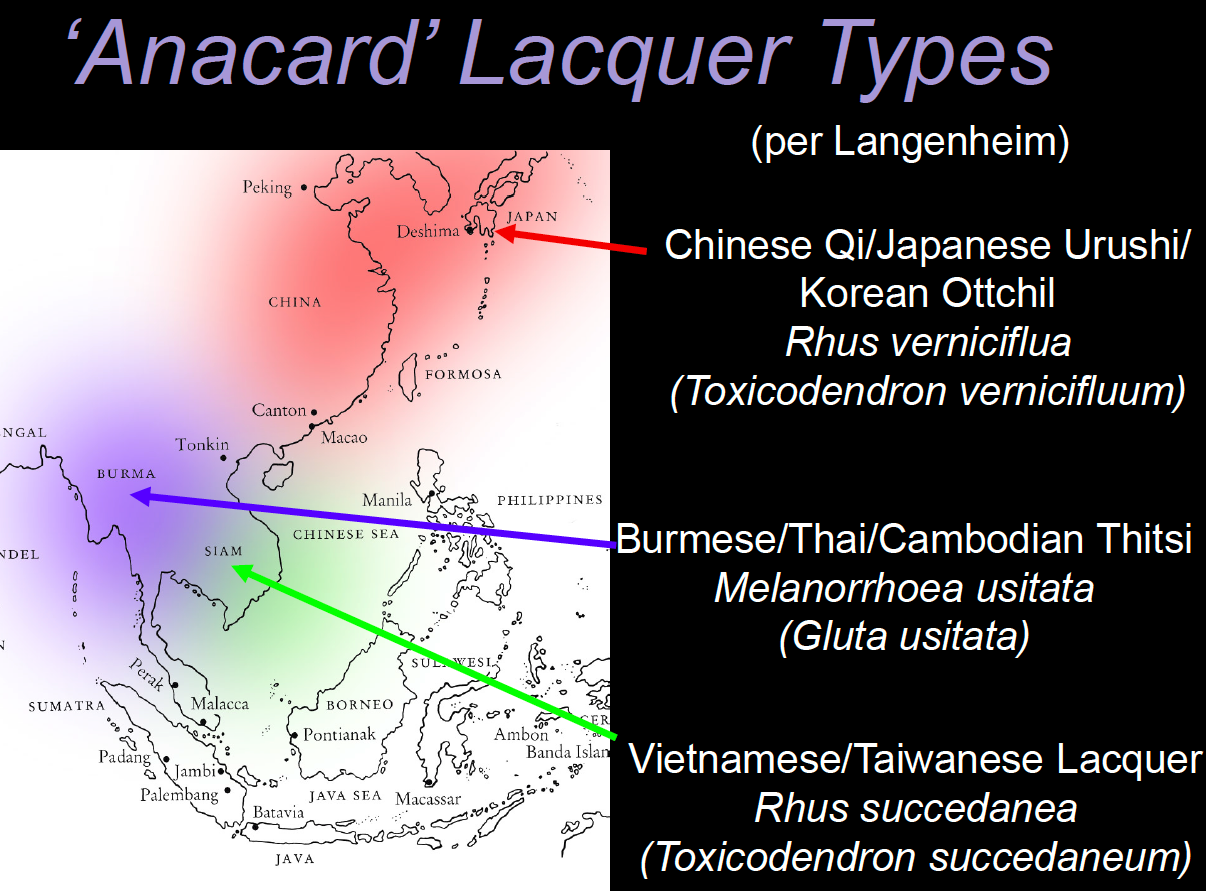

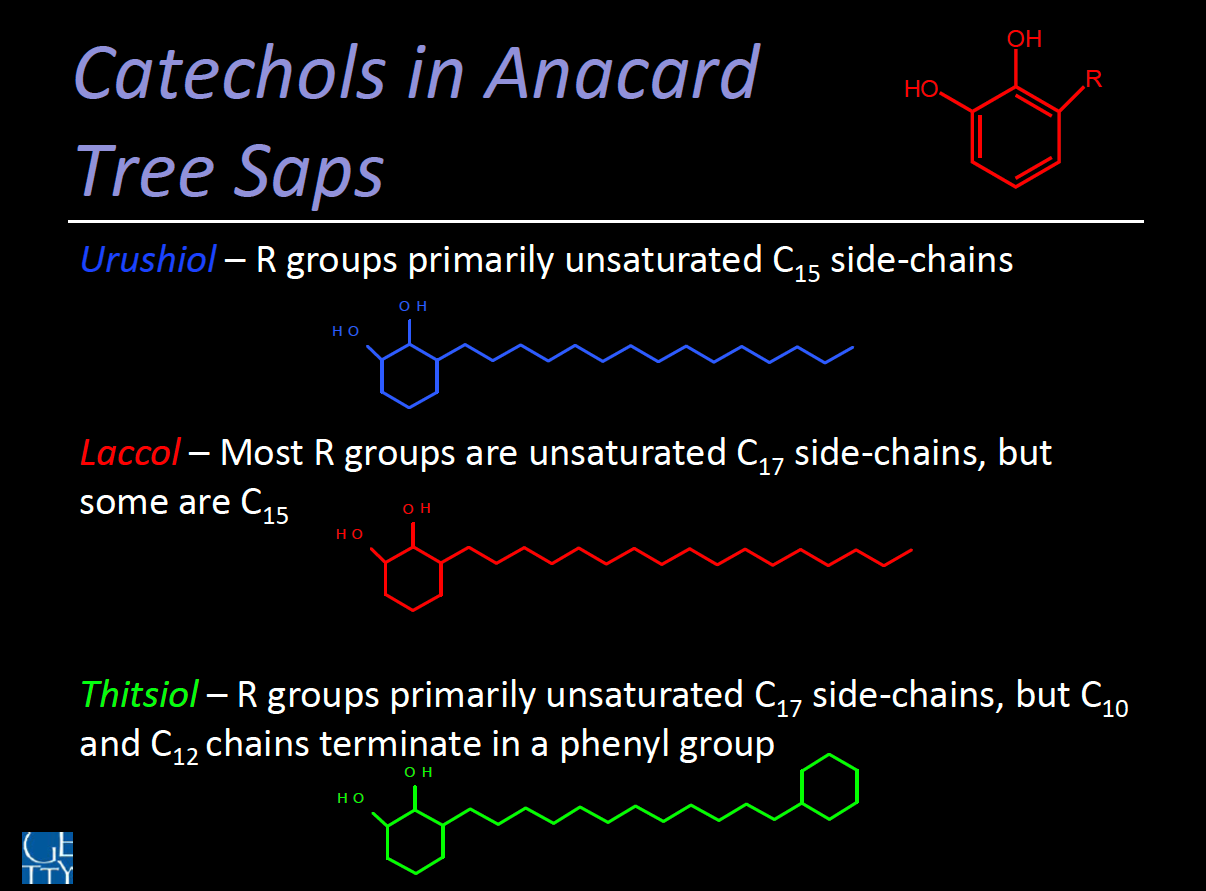

Asian lacquer is a sap obtained from lacquer trees. Lacquer trees can be roughly classified into three types. The main components of these sap are also different. Lacquer tree species are widely spread from Southeast Asia to East Asia. It is said that Asian lacquer causes rash. When these sap adheres to human skin, it may cause an allergic reaction.

-

Rhus verniciflua (Toxicodendron vernicifluum)

Common name: Lacquer Tree

This tree species naturally occurs in China, Korea, and Japan. The sap of this tree contains the resin urushiol, which takes in oxygen from the air and chemically polymerizes and hardens. Recent field surveys have increased the likelihood that this species is also growing in Bhutan. -

Rhus succedanea (Toxicodendron succedaneum)

Common name: Vietnamese Lacquer Tree

This tree species naturally occurs in Cambodia and Vietnam, and was planted in Taiwan from Vietnam. The main component of sap is laccol. The varieties of this tree species grow in Bhutan, China, Korea, and Japan as well, and are called Wax Tree because of a source of candle-making. -

Gluta usitata (Melanorrhoea usitata)

Common name: Burmese Varnish Tree

This tree species grows naturally in Myanmar and Thailand. The main component of sap is thitsiol.

A certain temperature and humidity are required for Asian lacquer to harden (dry). Unlike other "medium" or "binder", Asian lacquer does not dissolve in a solvent. While various natural polymers (like resins) harden through the evaporation of a solvent, and through the evaporation of volatile components, resin from the Toxicodendron sp. and Melanorrhoea sp. harden through a complex process of polymerization induced by the absorption of oxygen and moisture from its surrounding atmosphere. Once Asian lacquer hardens, it exhibits excellent resistance to water, heat, alcohol, solvents, acids, alkali, and Mold.

Harvesting and production of Urushi lacquer in Japan

While each country has its own sap procurement and purification methods, we will briefly introduce Japanese Urushi lacquer production method.

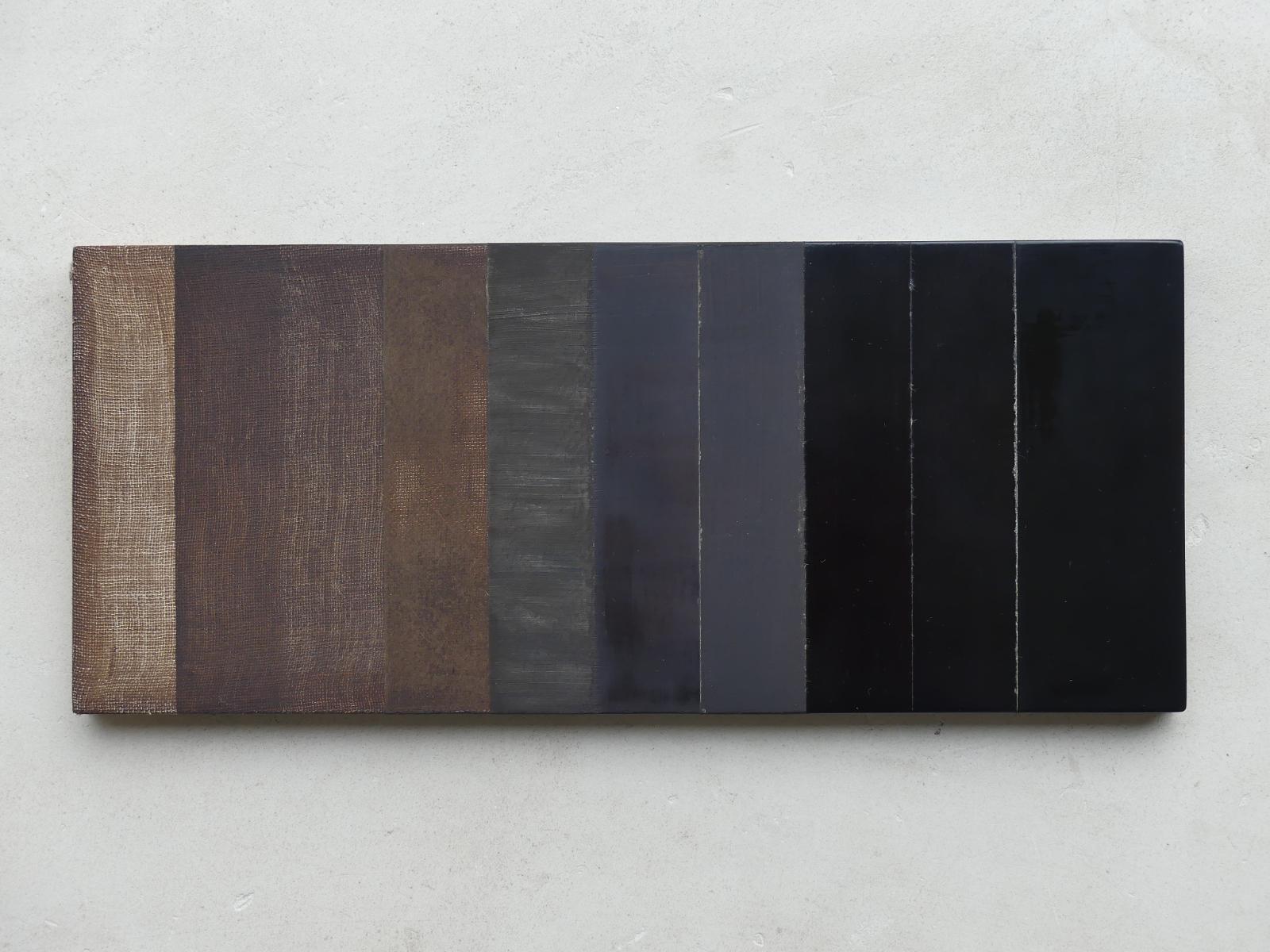

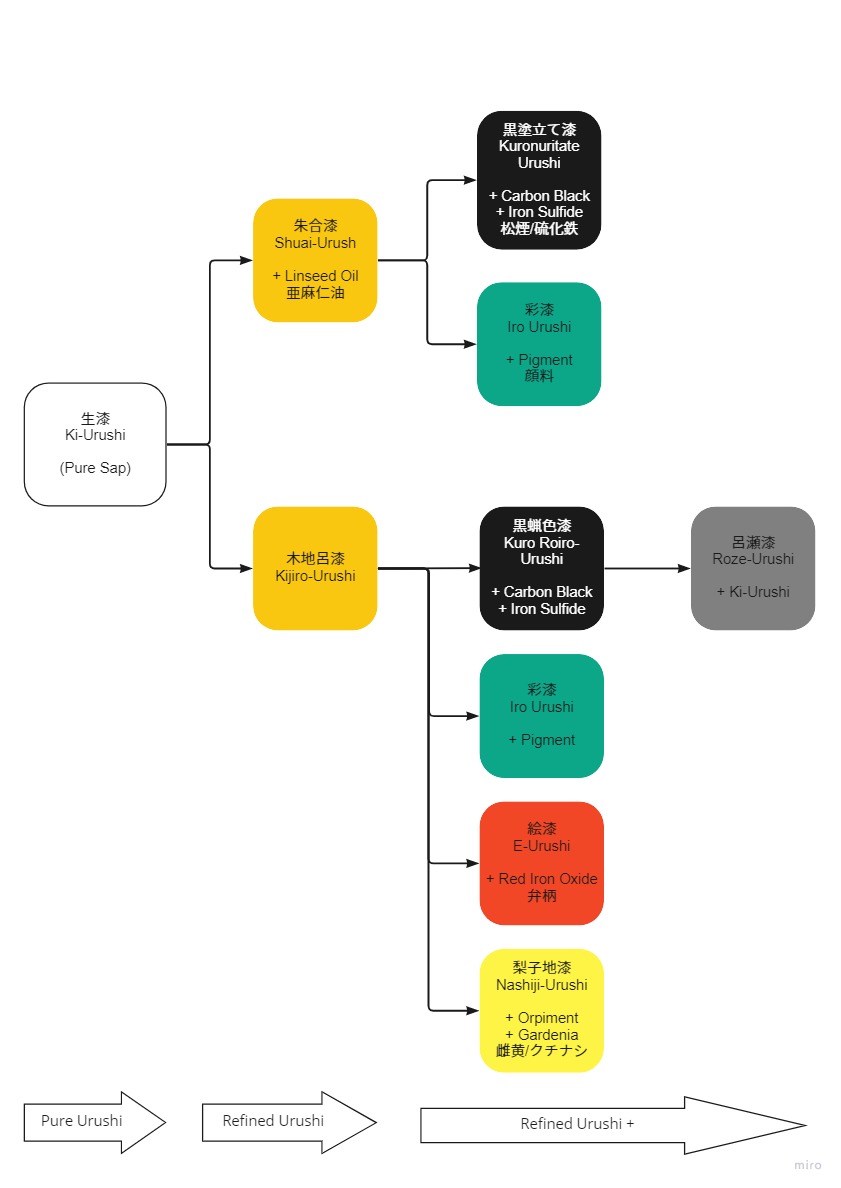

10 to 15 years after planting a lacquer tree (Urushi no Ki), one can start collecting sap. Urushi lacquer harvest is from May to October. The amount of sap that can be collected from a single lacquer tree is about 200 grams. The collected sap is filtered to remove impurities. This raw lacquer is called Ki-Urushi. After that, further purification can be done. By stirring the liquid of Ki-Urushi, the particles are made finer (Nayashi) while making the ingredients uniform, and heat is applied to gradually remove the water (Kurome). Lacquer refined in this way is called Kijiro-Urushi, or Suki-Urushi which means transparent lacquer. Coloured lacquer can be made by mixing pigments with Kijiro-Urushi or transparent lacquer with oil such as Shuai-Urushi.

※ Generally, when it is called Suki-Urushi, it often refers to lacquer mixed with oil.

Urushi Sorts

Urushi Lacquer Art process

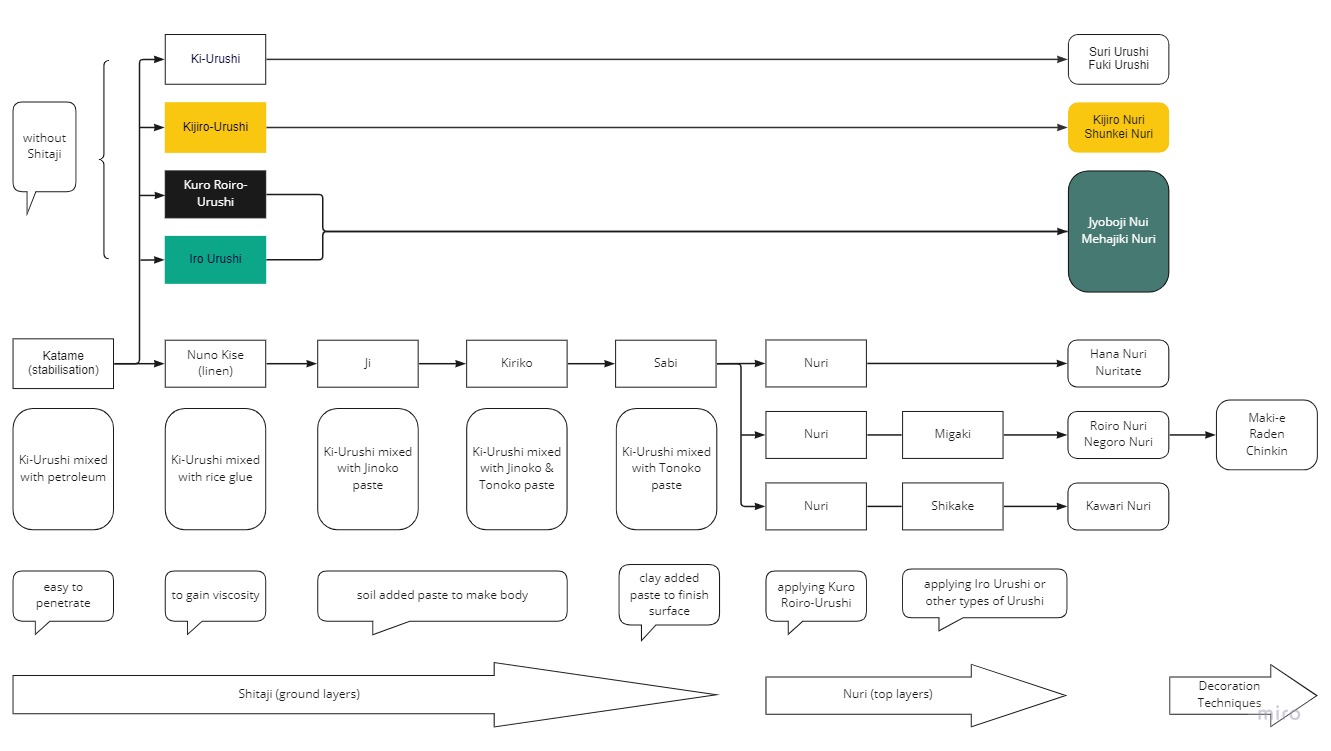

East Asian Lacquer Art has a wide variety of expressions and countless techniques. Although it is impossible to cover all of them, here we attempt to provide a general explanation of the main techniques applied to Japanese lacquerware. The common thing is that many layers of lacquer are applied to make substrate durable. The surface is basically finished with black lacquer. Decorating the black monotone surface is called Kashoku. The manufacturing of lacquerware can be broadly divided into the following four steps.

1) Tai (胎) substrate: making base materials in wood, bamboo, textile, paper, or leather.

2) Shitaji (下地) ground layers: mixing Ki-Urushi (raw lacquer) with soil, clay, etc., to make Shitaji paste, and then apply Shitaji on the substrate to give the body. Smoothing (sanding) the Shitaji to the desired shape.

3) Nuri (塗り) lacquering: applying black Urushi over the smooth surface. Sometimes coloured lacquer is applied over black Urushi. In some cases, the surface is finished without polishing. Further polishing to a mirror is called Roiro-migaki. The finishing of mirror surface without any Kashoku decoration is called Roiro-nuri.

4) Kashoku (加飾) decoration techniques: before Roiro-migaki, decorations such as Maki-e and Raden (mother-of-pearl inlay) are applied, and then polishing is applied over the decorations.